DMG MORI has introduced grinding technology in its duoBlock machines to create a machining center with the ability to mill, turn and grind in a single setup. Weekly fishing report illinois.

Grinding Options In Dmg 125 Fdw

After setting standards in technology integration with mill-turn technology for almost two decades, the machine tool manufacturer has now expanded its portfolio in this field to include a new variant with milling, turning and grinding (F-mill D-turn S-grind) capabilities.

As of now integration of the grinding technology is available for the size 80, 125 and 160 machines of the DMU / DMC FD duoBLOCK® series, thereby guaranteeing surface qualities of up to 0.4 µm. Milling, turning and grinding are carried out in a single set-up, so deviations resulting from retooling are also eliminated. This complete machining capability including grinding is further supported by exclusive DMG MORI technology cycles.

DMG MORI supports the grinding process of the FDS models in the duoBLOCK® series with DMG MORI technology cycles for internal, external and face grinding. Truing cycles expand the range of functions. Also new is an AE sensor (Acoustic, Emission) that guarantees maximum reliability and accuracy by detecting the first contact between the grinding wheel and the truing unit. The first contact between the grinding wheel and the component is also determined via the spindle load factor. DMG MORI has equipped the 1 300 litre coolant unit of the FDS machines with a centrifugal filter that catches even the finest particles (> 10 µm) from the grinding process.

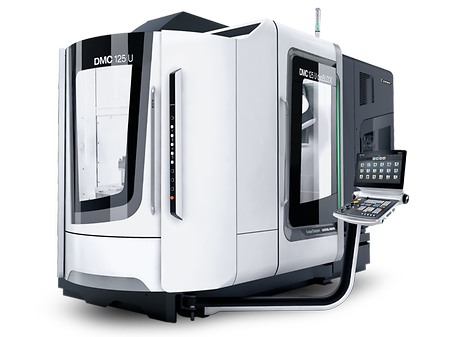

I've run a 125 FD for years and I never had any problems with cycle 800. I do run 3D quick set a few times a year. Or if I have a accident. My 125 horizontal don't have quick set but I do it manualy and never had any major errors when using cyle 800. DMG model DMC 125 FD 5-axis machining center High-speed, high-precision milling and turning center combines a direct-drive rotary table with full 5-axis milling for advanced capabilities. Quicktime player for mac adjust player speed slow. The high-speed pallet changer and precision fixturing system ensure maximum productivity.

DMG MORI supports efficient and productive complete machining comprising milling, turning and grinding with the aid of exclusive DMG MORI technology cycles, especially where grinding is concerned. The calibration cycle, for example, enables calibration of the truing station. Cycles for internal, external and face grinding plus truing cycles for truing the grinding wheel round off the offer. In addition new grinding wheel diameters can be defined automatically.

For more information contact Retecon Machine Tools on TEL: 011 976 8600 or visit www.retecon.co.za

Grinding Options In Dmg 125 Fda

Milling List

Grinding Options In Dmg 125 Fde

DMG MORI has introduced grinding technology in its duoBlock machines to create a machining center with the ability to mill, turn and grind in a single setup. Weekly fishing report illinois.

Grinding Options In Dmg 125 Fdw

After setting standards in technology integration with mill-turn technology for almost two decades, the machine tool manufacturer has now expanded its portfolio in this field to include a new variant with milling, turning and grinding (F-mill D-turn S-grind) capabilities.

As of now integration of the grinding technology is available for the size 80, 125 and 160 machines of the DMU / DMC FD duoBLOCK® series, thereby guaranteeing surface qualities of up to 0.4 µm. Milling, turning and grinding are carried out in a single set-up, so deviations resulting from retooling are also eliminated. This complete machining capability including grinding is further supported by exclusive DMG MORI technology cycles.

DMG MORI supports the grinding process of the FDS models in the duoBLOCK® series with DMG MORI technology cycles for internal, external and face grinding. Truing cycles expand the range of functions. Also new is an AE sensor (Acoustic, Emission) that guarantees maximum reliability and accuracy by detecting the first contact between the grinding wheel and the truing unit. The first contact between the grinding wheel and the component is also determined via the spindle load factor. DMG MORI has equipped the 1 300 litre coolant unit of the FDS machines with a centrifugal filter that catches even the finest particles (> 10 µm) from the grinding process.

I've run a 125 FD for years and I never had any problems with cycle 800. I do run 3D quick set a few times a year. Or if I have a accident. My 125 horizontal don't have quick set but I do it manualy and never had any major errors when using cyle 800. DMG model DMC 125 FD 5-axis machining center High-speed, high-precision milling and turning center combines a direct-drive rotary table with full 5-axis milling for advanced capabilities. Quicktime player for mac adjust player speed slow. The high-speed pallet changer and precision fixturing system ensure maximum productivity.

DMG MORI supports efficient and productive complete machining comprising milling, turning and grinding with the aid of exclusive DMG MORI technology cycles, especially where grinding is concerned. The calibration cycle, for example, enables calibration of the truing station. Cycles for internal, external and face grinding plus truing cycles for truing the grinding wheel round off the offer. In addition new grinding wheel diameters can be defined automatically.

For more information contact Retecon Machine Tools on TEL: 011 976 8600 or visit www.retecon.co.za

Grinding Options In Dmg 125 Fda

Milling List

Grinding Options In Dmg 125 Fde

Grinding Options In Dmg 125 Fdx

| Count—– | Manufacturer—– | Type—–—-—-————- | Feature |

| 2 | DMG | DMC 100u duoBlock | 5-axis universal 120 Tools |

| 2 | DMG | DMC 80U duoBlock | 5-axis universal 80-120 Tools |

| 1 | DMG | DMC 80U duoBlock | 5-axis universal 10 Pallets-240 Tools |

| 1 | DMG | DMC 125 FD | 5-axis, milling/turning table with pallet system |

| 1 | DMG | DMC HSC75 | 5-axis high speed |

| 2 | DMG | DMC 55 H duoBlock | 4-axis horizontal with System 3R Quick Change Pallet Stations |

| 1 | DMG | DMC 64 v | 4 axis Vertical with Rotary Axis (System 3R Pallet System) |

| 1 | DMG | DMC 104V | 4 axis Vertical with Rotary Axis (System 3R Pallet System) |

| 1 | DMG | DMC 100 V hi-dyn | 3-axis vertical |

| 1 | DMG | DMU 35M | 3+ axis vertical |